Call us: 08069546895

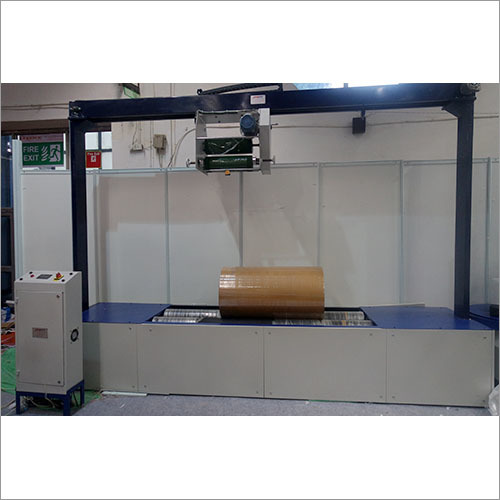

Mini Reel Wrapping Machine

175000 INR/Unit

Product Details:

- Product Type Wrapping Machine

- Material Metal

- Voltage 220 Volt (v)

- Color Cream and Red

- Warranty Yes

- Click to View more

X

Mini Reel Wrapping Machine Price And Quantity

- 1 Unit

- 175000 INR/Unit

Mini Reel Wrapping Machine Product Specifications

- Wrapping Machine

- 220 Volt (v)

- Metal

- Yes

- Cream and Red

Mini Reel Wrapping Machine Trade Information

- 100 Unit Per Week

- 1 Week

- All India

Product Description

Our clients can avail from us premium quality Reel Wrapping Machine. These machines are highly demanded by packaging industries for their excellent performance and durability. We manufacture these machines by making use of high quality stainless steel, sourced from the top vendors of the industry. Latest tools and machines are used by our skilled professionals to manufacture these machines. Owing to its non-corrosive nature and compact design, the Reel Wrapping Machine is widely appreciated in the international market.

Features of Reel Wrapping Machine:

1. Wrapping time can be preset

2. Outstanding packing efficiency

3. Fully automatic

FAQ:

Q. What is a reel wrapping machine?

Ans: A reel wrapping machine is an industrial packaging machine used to wrap various types of cylindrical or reel-shaped products with a protective film or material. These machines are commonly used in industries such as printing, paper, textiles, and more to secure and protect rolls of materials.

Q. What are the benefits of using a reel wrapping machine?

Ans: Reel wrapping machines offer several advantages, including increased efficiency, reduced labor costs, enhanced product protection, and improved load stability during transportation.

Q. How does a reel wrapping machine work?

Ans: Reel wrapping machines typically work by rotating the reel or product while dispensing and wrapping it with stretch film or another packaging material. The machine can be either manual, semi-automatic, or fully automatic, depending on the specific model and application.

Q. What types of materials can be wrapped using a reel wrapping machine?

Ans: Reel wrapping machines are designed to wrap various materials, including paper rolls, plastic film rolls, textile rolls, wire reels, cable reels, and more. The type and specifications of the machine may vary based on the material being wrapped.

Q. What is the difference between manual, semi-automatic, and fully automatic reel wrapping machines?

Ans: Here is the differences between these two machines:

a. Manual machines require an operator to control the wrapping process, including the application of film and starting/stopping the machine.

b. Semi-automatic machines automate some aspects of the wrapping process, such as film application, while still requiring operator intervention for loading and unloading.

c. Fully automatic machines can perform the entire wrapping process without operator intervention. They often feature conveyors and automatic film cutters.

Q. What are the key features to consider when purchasing a reel wrapping machine?

Ans: Key considerations include the machine's wrapping capacity (maximum reel size and weight), film dispensing method (pre-stretch, power pre-stretch, etc.), control options, safety features, and the level of automation required for your specific application.

Q. Can reel wrapping machines handle different types of films?

Ans: Yes, many reel wrapping machines can handle various types of packaging films, such as stretch film, shrink film, or even paper. The choice of film depends on the specific requirements of your product and application.

Q. Are there safety precautions to follow when using a reel wrapping machine?

Ans: Yes, safety is paramount. Operators should be trained in the proper use of the machine, and they should follow safety guidelines related to machine operation, loading/unloading, and any moving parts. Regular maintenance and inspection are also essential to ensure safe operation.

Q. What maintenance is required for a reel wrapping machine?

Ans: Regular maintenance may include cleaning, lubrication, and inspection of the machine's components. You should follow the manufacturer's recommendations for maintenance schedules and procedures.

Q. Can reel wrapping machines be customized for specific requirements?

Ans: Yes, some manufacturers offer customization options to tailor the machine to your specific needs. This can include adjustments to accommodate different reel sizes, automation levels, and control options.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese